|

|

|

High altitude wind:

the long awaited energetic “miracles” [1] |

|

Massimo Ippolito [2] - KiteGen Research

s.r.l. [3] August 2016 |

|

KiteGen is certain to have seized the holy

grail of sustainable energy. We registered more than 40 international

patents, have been cited in more than 350 scientific publications[4], and,

from different points of view, corroborate and complete our thesis. KiteGen is the only Italian company (and the only one

focused on energy innovation in the world) in 2015 Cleantech

100 Company's "ones to watch" (no Italian company is present in

2016 list). We have been granted the ENI award[5]. These awards and

recognitions were granted after technical diligences, and the various proofs

of concept are real, public and documented. But this technology has not yet

breached into the system, we still lack support from institutions, and The

Netherlands is the only country offering academic courses on this subject.

High altitude wind energy is a grand project needing to step up to a

completely new level, from research to industry, with the entire onus, as

well as the impact on employment, implied by this change. In 2006, KiteGen manufactured a generator already competitive,

even in its first stages of development, with solar panels for both costs and

energy supply reliability. Nevertheless, we got to be helpless witnesses

while all institutional support went to conventional wind power sources and

photovoltaic. It's easy to figure out the charismatic role and enthusiastic

growth this new energy device could have had, had it been granted any kind of

start-up support. KiteGen kept up working on design

and validation on its own, a task for a team much bigger than the one that

actually accomplished it. Now theoretical basis, prototypes, intellectual

property, technology package, are real assets on which the restart will be

based, and with which we can spread the world of the change it could bring. KiteGen is an opportunity Italy and Europe cannot pass

up, due to their serious and persisting energy deficit. Seems like the idea

that energy is a "problem we cannot solve, yet crucial for every country

and their economy" gets stronger by the day. We here try to propose

again the rationale of KiteGen Project, the state

of art, and the trouble we met while trying to spread that, which is not just

an opportunity anymore, but, for anyone versed enough in energy sector,

without doubt the primary energy source that will feed the future of

civilization. |

[1]https://www.gatesnotes.com/Energy/Energy-Miracles We Need Energy

Miracles By Bill Gates | June 25, 2014 +39 348 0194813 [3]KiteGen Research s.r.l. cso Lombardia 66/c San Mauro Torinese +39 011 9415745 [4] https://scholar.google.it/scholar?hl=it&q=kitegen&btnG=&lr= [5]http://www.ilsole24ore.com/art/tecnologie/2010-06-10/domatore-aquiloni-081200.shtml?uuid=AYwRIPxB |

SUMMARY AND PRESENTATION OF THE PROJECT

|

|

Sequoia Automation is an

industrial engineering firm specializing in the design of software and

electrical/electronic, control and mechanical systems. It has conducted

numerous research and development activities in the past and has also managed

European funded research projects. Its involvement in numerous activities in

the field of energy has given it a profound knowledge of the industry. These

include: control and synchronization of gas turbine generators, robotic

maintenance of high voltage lines, autonomous energy systems, supercapacitors, inertial platforms and energy

regeneration systems in vehicles. Moreover, as a company operating at the

service of KiteGen, Sequoia has the advantage of

forty years of experience as a mechatronics and

R&D design firm. It has accumulated the extensive multidisciplinary

knowledge required for the design and construction of next-generation systems

that integrate various fields of expertise. The company’s assets include

artificial intelligence systems, physics and fluid dynamics engines, inertial

platforms, electric vehicles and nonlinear multi-predictive numerical

controls, parallel kinematic robots and supercapacitors. Since 2008, Sequoia has been

almost exclusively managing the ambitious and complex KiteGen®

project centred on tropospheric

wind power. It has adopted this as a mission as a result of meetings at the

highest levels of European research and with key historical figures in

Italian electrical energy, who expressed their support for Sequoia’s

commitment as an entity certainly capable of meeting the challenge. The

objective has gone beyond a mere corporate project to become a profoundly

ethical and collective mission. With this attitude, Sequoia has invested

several million euros over time in the industrial

training of hundreds of candidates and interns, with the conviction of being

able to develop around them the professional offer necessary for the project.

The success of this strategy surpassed all expectations, generating hundreds

of business initiatives worldwide that are ready to collaborate in a multinational

initiative. The activity conducted so far has

produced a substantial “technology package” describing the innovation in

detail, which has gained significant value from the addition of the physical

and experimental validation of all the steps leading to the distillation of

the knowledge. This has made possible the industrialization and production of

the generators in their final form, with a predeterminable

time to market, a result that has changed the current corporate mission. Other industrial companies

specialized in complementary fields have recently joined Sequoia. These include a composite

materials company with twenty years’ experience in the field of advanced

composites for the aeronautics sector. Throughout its years of activity, the

company has experienced continuous growth in terms of turnover and staff.

This has been possible thanks to investments in equipment and facilities that

have enabled it to gain important contracts in the aeronautical sector and

become a supplier for large aircraft manufacturers, such as Boeing. Thanks to its elevated skills and

experience in the field of advanced composites, it has acquired new contracts

in both the aerospace and the industrial sector, where structures and

components that were once made of metal are now being replaced with much

lighter and more durable composite parts. The markets it serves ranges from

the aeronautic and automotive sectors to automation, printing, packaging,

railways and energy. The scope of the specialist

composite company is to support, produce and industrialize products that

require improvement in terms of technology and performance. This can be

achieved by replacing traditional materials with advanced composite

materials, or by designing components made with these new technologies. The KiteGen wing, which is a completely new and extreme

object, can reap the benefits of this extensive experience, as well as the

specialized equipment designed for working on large monolithic composites. |

OBJECTIVES AND STRATEGY OF THE PROJECT

|

|

With the exception of

hydroelectric power, which is, however, limited in its application due to the

relative scarcity of sites and viable conditions, humanity has not yet

managed to identify new sources of renewable energy that are not dependent on

subsidies. These contribute to the deterioration of the economic downturn,

reducing consumptions and driving away various industrial initiatives from

the country, together with the respective jobs, due to their distorting

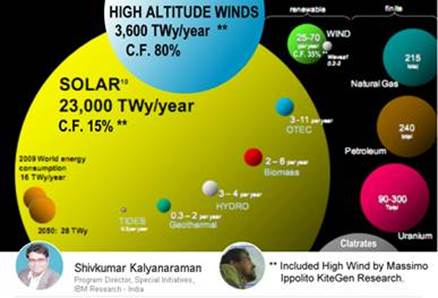

effect on energy prices. Within the energy sector, the project’s objective is

the industrialization and management of the production of wind generators

that can extract energy from the troposphere. This extends up to about 9,000m

above sea level and has been shown by comparative analyses to be the

cleanest, most concentrated and most abundant natural energy resource. For

this purpose, our research has examined technological methods to make use of

this mechanical energy resource, equivalent to over 200 times the current

basic needs of human kind. The work has focused on architecture, technologies

and materials for the development of these wind machines, and solutions have

emerged with dramatic improvements in performance compared to existing

methods. These take advantage of the wide availability of new mechatronic intelligence in order to exploit the kinetic

energy of high altitude winds. This produces the following

advantages: * Particular lightness and

dematerialization of the generators (only 20 tons as compared to 1,500 tons

for an equivalent wind turbine), thus greatly facilitating production,

installation and maintenance logistics. * Access to substantially larger

wind front areas compared to traditional wind turbines, allowing a much

greater quantity of energy to be harvested, even with winds considered not

very productive. * Access to altitudes where the

wind has greater intensity and consistency than that available to wind

turbines. * Modulable (non-intermittent) baseload

behaviour that multiplies the intrinsic value of

the energy produced. The concepts

developed to meet these requirements, and the respective physical and

experimental validations, have led to the filing of 40 patent families

acknowledged as innovative and industrially applicable, with over 3,000

extensions worldwide. This provides the knowledge base for a desirable and

radical transformation of wind energy production processes and the entire

wind energy sector, as well as a reduction in energy production costs by a

factor of 10, with LCA studies showing an ERoEI 30

times greater than that of wind turbines. The system is

composed of three main parts: a generator robot based on the ground, strong,

lightweight cables of sufficient length to reach the typical operational

altitudes (1,000-2,000 m), and an arched semi-rigid, tensile structural power

wing large enough to provide a tensile force of 300 kN,

with adequate efficiency to allow cross wind flight at 80 m/s. After

extensive studies on the cable requirements, the fatigue behaviour

induced by the winches and the properties of the most innovative fibres on the market, the choice fell on

ultra-high-molecular-weight polyethylene (UHMWPE). This fibre

fully meets the specifications for durability and strength. The generator on

the ground has two lines of alternators that operate pulleys and winches on

which the cables are wound, with the wing connected to the opposite ends by

means of bridles. The generator robot has a pair of opening mobile arms with

2 degrees of freedom for the purpose of keeping the wing suspended. Takeoff

can be performed by exerting sufficient traction on the cables or by rotating

the arms to overcome stall speed through centrifugal force. During takeoff

the wing moves away tracing figure 8 trajectories (lemniscate)

and rises up until it finds sufficient wind (cut-in – about 4 m/s) to produce

a nominal force of 150 kN on each cable. At this

point the cables can unwind at a speed equal to the wind speed less the

cut-in speed in order to maintain a constant nominal force. Thus there is a

power on each cable of 150*v kW, reaching the nominal 3 MW when the unwinding

speed v equals 10 m/s (wind speed of 14 m/s). This mechanical power is

transformed into electrical power by alternators connected to pulleys and

reels. When the cables are completely unwound, the sideslip manoeuvre is performed (one of the innovations described

in the patents), which allows the cables to be rewound differentially (one of

the cables is kept a few dozen metres shorter than

the other), causing the wing to assume the shape of a flag (thanks to its articulated

rigidity) and lose its aerodynamic properties to minimize resistance during

the recovery of the cables. During this phase

the alternators act as motors, with an energy consumption of 1% of that

produced in the active phase. Once the wing has returned to a minimum

altitude (programmed based on wind conditions) the length and tension of the

cables is rebalanced, the wing recovers its natural arc shape and aerodynamic

properties, and once more provides the necessary nominal force and mechanical

power to perform further cycles. The major innovation factors contained in

the patents include devices designed to increase the flight stability and

control, such as radio controlled ailerons and bridles with programmed

elasticity to continuously optimize the wing’s angle of attack, as well as

solutions to reduce the resistance of the cables, giving them an aerodynamic

profile. Other highly

innovative aspects include the use of inertial platforms (an accelerometer,

gyroscope, magnetometer and altimeter integrated into a miniaturized device).

These devices, positioned on the wing and on the mobile parts of the

ground-based generator and linked to the control unit via radio, allow the

computer to create accurate real-time dynamic models of the mechanical and wing

parts through the application of mathematical operators and Jacobian matrices, to predict their behaviour

in real time and adjust stresses and propagation on the various parts. For

example, a gust of wind that would cause a violent increase in the force transmitted

by the wing through the cables, with the impulse propagated along the cables

at the speed of sound, would be detected by the accelerometers and

transmitted to the ground at the speed of light. This allows stability of

control and dampening, e.g. prompt release of the cables to neutralize the

incoming impulse. |

|

|

The “Wings &

Power” project, co-financed by the region of Piedmont with European funds

(but reduced from the original €7 million to less than €3 million due to the

institution’s financial needs) and successfully concluded in March 2016,

contributed in part to the development of the technological solutions based

on the inventive teaching of the patents and the consequent achievement of

TRL7. Eighty components containing the main innovation elements featured in

the patent portfolio have been designed, manufactured and validated (now

grouped into 10 machine sub-assemblies). Recognition of this level of

technological advancement was confirmed by the signing of an important

contract with a chemical multinational for the purchase of hundreds of

generators, subject to the subsequent achievement of TRL 9. The steps to be

taken in this respect are the establishment of a production line capable of

manufacturing the product with industrial quality and of re-testing it in

operational conditions to meet the conditions of the existing contract and

other contracts, which in all likelihood will be easily obtained through with

establishment of an energy production track record. It offers reliability,

safety and economic sustainability only possible for a product with the

highest industrial standards. The region of Piedmont has numerous other

outstanding industrial realities capable of handling partial or entire

sub-assemblies and providing the necessary quality for their production. The

proposed initiative, in addition to distributing the innovations produced

during the R&D phase among local companies, which can also have

repercussions on various other products, together with the unprecedented

performance of the generator, will help create linked activities and a

subcontracting sector engaged in the production of thousands of machines per

year for export all over the world, with the recruitment of tens of thousands

of workers with the medium and high levels of specialization typical of the

aerospace industry. |

TECHNOLOGICAL

FIELD

|

|

The project can be

considered a fusion between mechatronics and aerospace.

This combination often encounters a cognitive bias that tends to raise or

relegate it to the sphere of basic research, although efforts to provide

information and updates soon lead to recognition of its industrial

significance and readiness. The basic research was completed thanks to

intense collaboration between Sequoia, some hi-tech companies, and

researchers and interns from the Universities of Turin, Milan, Leuven,

Stuttgart, Delft, Wuppertal, Stanford, etc., and initially catalysed by research funding from the region of

Piedmont. In the event of its programmatic adoption, the impact of this new

wind technology on the socio-economic system could be successfully replicated

on international markets, providing a valuable response to the ongoing economic

crisis and decline in employment, since energy, and only that with low

production costs, is what ultimately drives human progress. The power wing is

the focus of the collaboration with our composite manufacturing partner

company. In the economy of the generators, this is a consumable material,

like the cables, with an envisaged annual rate of replacement. These

circumstances and opportunities outline a synergistic future, where the robot

generators are installed in production sites and the periodic supply of wings

links the power generation companies operating in the local area with the

firms manufacturing the machines and the wings. A business model can be

envisaged that includes maintenance and the supply of consumables. |

TECHNICAL

FEASIBILITY

|

|

In terms of publications, KiteGen has given rise to over 300 documents and active

collaboration with dozens of academic institutions. Istituto

Sant’Anna of Pisa and the University of Bologna

have prepared an orientation document: Airborne Wind Energy

Systems: A review of the technologies Antonello Cherubini(a), Andrea Papini(a), Rocco Vertechy(b), Marco Fontana(a), a) PERCRO SEES, TeCIP Institute, Scuola Superiore Sant׳Anna, Pisa, Italy b)

Department of Industrial Engineering, University of Bologna, Italy KiteGen undoubtedly represents a new

development in the field of energy, with a feasibility, scalability and merit

factor that can be calculated and assessed in advance with great reliability,

as can the steps and investments required to implement it as an energy

support at the service of the community, with analytical data already

available in sufficient detail from KiteGen.

Unfortunately, due to the totally new and multidisciplinary nature of the

system, the institutions cannot provide the necessary and comprehensive

competences for its systematic adoption, both in terms of investment and of

research. This makes it difficult to establish a complete supply chain and

the procurement of human resources capable of acquiring the necessary

knowledge and determination. From a close analysis of the underlying

dynamics, three types of obstacles can be seen that delay the emergence of

the technology, which in the light of the current and not-so-bright scenario

of typical renewable sources remains an obvious and essential source. The first obstacle is undoubtedly

due to the particular interests of certain economic sectors, which are

opposing the KiteGen concept while they can, with a

considerable financial commitment. Surprisingly, these are parties involved

with sources currently considered as renewable and that benefit from support

policies for their deployment. KiteGen is the first

ever source which, once the initial technological learning phase is

completed, will no longer need aid but will itself become a powerful economic

engine, dramatically abandoning the subsidy policy. The second obstacle that involves KiteGen is connected with politics and ideological

organizations. Surprisingly, these are groups related to scaremongering over

climate, the environment, overpopulation and dwindling resources. Knowing KiteGen very well, they should be supporting it instead

of opposing it and feeding on the consensus that comes from an alarmist and

superstitious attitude. They become increasingly pervasive, getting considerable

power and economic benefits, as long as the various alarms remain without

effective solutions, and KiteGen undoubtedly

represents a threat to these privileges. The third one has

already been mentioned, namely the difficulty of grasping a highly multidisciplinary

and unfamiliar concept. KiteGen would be able

to address these difficulties effectively if attitudes more open to dialogue

could be established between the evaluation sessions and the project. To this

end, a review is provided below for better prior clarification of the main

points confirming the project’s technical feasibility, which, from our

experience, tend to disorient those unfamiliar with the design and sizing of

the generating machines and the wing in the light of the design specifications: |

|

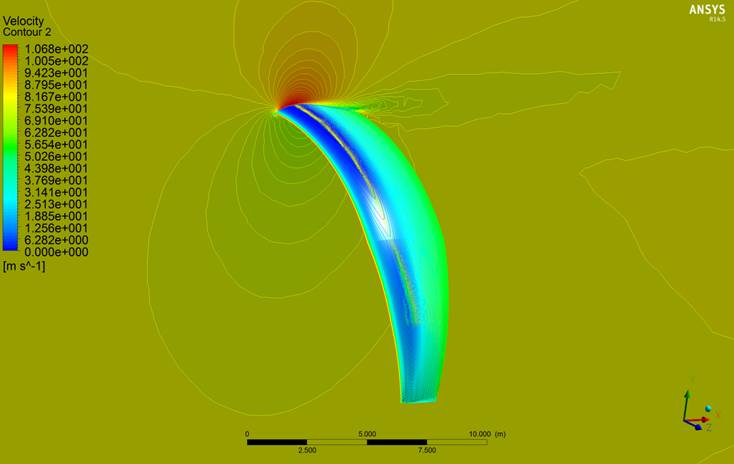

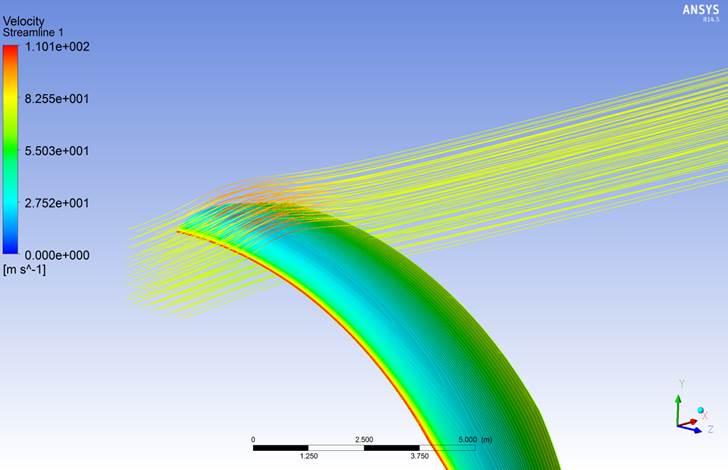

Lift,

flight speed and axial load of the arched semi-rigid wing |

|

Although this is the

topic most developed at the level of scientific literature, with substantial

formalization and numerical examples, the difficulty normally remains of

distinguishing the behaviour of a load-bearing wing

from a mere parachute, leading to misunderstandings that are difficult to

resolve. The axial force propagated on the cables depends mainly on the

wing’s flight speed squared and only in a linear direction from the surface

of the wing. The flight speeds are in the order of 80m/s. The forces generated

amount to tens of tons of traction and have been specifically studied due to

their relevance to the production of energy. |

|

|

|

Duration,

repeatability and reliability of flight |

|

This appears to be

another thorny issue, and is extremely debated in the numerous online

communities where KiteGen is discussed. Here we can

state emphatically that the flight is extremely safe and reliable. It should

be borne in mind that the wind seen from the wing is always stabilized by the

strategy of unwinding the cables, so that even a sudden and total absence of

natural wind would not change the wing’s flight parameters as the system can

retract the cables, thereby creating the necessary wind for the manoeuvres. Obviously, when there is prolonged absence of

natural wind the wing has to be taken down in order not to unnecessarily

consume the energy required to keep it in flight. |

|

Take

off and handling of the wing on the ground |

|

The take off function has been

brilliantly resolved by KiteGen, with an extremely

reliable procedure that can also be interrupted or aborted after takeoff

without causing damage to the wing or to the robot. Takeoff of the large

power wing, which is rightly considered the most complex and risky manoeuvre, is one of the issues that have been

successfully resolved, although in this case KiteGen

has suspended the normal disclosure of its discoveries to the international

scientific community. Its role as a first mover and prime innovator in the

industry is not given the recognition and respect it duly merits. This has

led us to resume the natural and customary privacy procedure regarding

confidential information. |

|

Tensile

structural strength and durability of the wing |

|

The wing chord length is currently

4 metres; by identifying the various sections and

materials that compose the wing, it has been possible to validate its

strength, providing a safety factor aligned along the entire kinematic chain,

which includes the cable hooks, reinforcement patches, hinges on the flexible

joint segments and wing sections. |

|

Strength

and durability of the UHMWPE cables |

|

The ultra-high-molecular-weight

polyethylene has been extensively tested in conditions of use, with measures

taken to extend its service life. The results are in line with the

theoretical predictions and indicate over a year of use before scheduled

replacement. |

|

Aerodynamic

drag of the cables during flight |

|

This point has undergone a recent

theoretical evolution that has been very positive for the project, as the

scientific literature has always simplified the aerodynamic model, combining

the drag of the ropes and that of the wing to arrive at a particularly unfavourable overall parameter, which, however, was not

validated in real tests. A complete and comprehensive mathematical model has

allowed us to provide a usable theoretical validation and to document a

further advantage of the KiteGen solutions, in that

the use of the double cable provides a higher safety standard than a

redundant system without any significant drawbacks. |

|

Functions

and load of the stem |

|

KiteGen, having exposed the technology

and opportunities to the public, is often subjected to baseless criticism,

such as the misinterpretation of the function of the robot arms. These arms

perform the function of supporting the wing on the ground, as it weighs about

300 kg, and are never involved in the operational forces of the system in flight,

as the arms always remain collinear to the cables, imparting at most a normal

force required for cable measurement and tension control operations, and thus

in reality the arms are sensors. |

|

Load on

the first idler pulley |

|

All the load of the

cables is conveyed through the stem to the first pulley, which is positioned

in a central position to the fifth wheel so that the loads from the cables do

not place any stress on the structure due to variations in wind direction or

flight altitude. |

|

Angle

of wrap and load on the pulley train |

|

This is already a more enlightened

and informed exception, raised by only a few of our interlocutors. This

aspect is particularly developed in KiteGen and has

led to the filing of two new patents for high-efficiency pulleys. The

function of the pulleys fitted to the alternators is to transfer the flow and

offload the tension of the cables, transforming it into motor torque. |

|

Generating

and rewinding power, duty cycle |

|

As the wind speed varies, so does

the productive duty cycle. Since the rewinding speed has been sized to 20m/s

and the maximum unwinding speed in the production phase to 10m/s, it can be

calculated that the duty or pumping cycle from one extreme is divided into

one third of the time for rewinding and 2 thirds for traction. The power

required for retrieving the wing in sideslip is 50 kW. Efficiency of the

conversion of the mechanical power into electricity The mechanical power

conveyed by the cables is converted by multipolar

alternators with torque control and feedback on speed and combined position. Flight

control. The control system

is divided into a HAL (hardware abstraction layer) and a high-level procedure

that decides the path of the wing through the airspace. The calculation

methods are all based on quaternions, which are not

susceptible to gimbal lock, eliminate singularities

and possible ambiguities in the geometric interpretation of the signals and

trace orientations up to ± 4π. The high-level procedure

was created with two simultaneous settings, the first is an analytical

control provided with artificial intelligence and the second an intensive

calculation approach with real-time physics and fluid dynamic engines, which

implement a non-linear control based on multiple models, called predictive

agents. CONDITIONS OF QUALIFIED RESEARCH

The previous

activity has been carried out by and for KiteGen

with the following results: * The first HAWP

(high altitude wind power) initiative worldwide to produce abundant

electrical energy through this novel method, already in 2006, through a

research prototype developed internally and then shared with Polytechnic of

Turin as the experimental and study base for dozens of master’s and doctoral

degree theses. * The first

initiative in the world to have completed the particularly efficient yoyo or

pumping kite cycle with sideslip, selected after testing the alternatives and

the implementation and cycle time. * The first in the

world to create an algorithmic control based on artificial intelligence and

an inference engine demonstrating automatic piloting. * The first

worldwide to create a high computational intensity control based on parallel

computing and physics/fluid dynamic engines in real time to implement and demonstrate

non-linear and multi-predictive control. * The first to

demonstrate automatic piloting of the wing solely through the sensitivity of

the ground-based stem to the direction of the cables, which has become a

redundancy support in sensor fusion. * The first

worldwide to achieve totally instrumental take-off and landing without any

human intervention. * The first and only

initiative to have collected and validated sufficient system specifications

and to conclude the basic research stage in favour

of industrialization on a utility scale. * The first and only

initiative to design, build and validate a large-scale, high-efficiency

composite power wing suitable for energy production, in line with and derived

from the high specialization in aerospace in the local region. * The first and only

initiative to have completed its final designs at a level sufficient to

launch batch production of systems and wings of industrial quality and

reliability. * The sole

intellectual property owner of the various HAWP concepts and the key

technologies for their implementation. * The sole owner of the

KG-Carousel concept, which offers the GW scale generators. Nevertheless, the

following issues still need to be addressed: broadening of awareness and

understanding of the technology, introduction of the technological learning

curve and the tropicalization of the machines, and

further scalability, both towards greater power levels and in terms of making

the system more compact. IMPORTANCE OF THE INNOVATIVE POTENTIAL OF THE

PROPOSAL

With KiteGen we have documented certainty of finally having

the most precious gift for mankind: an abundant, economical and sustainable

source of energy. The proposed technology has the

capacity to fully meet the needs of the global electricity market, guaranteed

by a natural “field” with a potential hundreds of times greater than human

needs, with no adverse affect on weather patterns and global climate (ref.

Ken Caldeira Stanford University). The low capital

cost of the generator and the fact that the maintenance cost is proportional

to the energy produced is a hopeful sign that the technology will have a

beneficial dampening effect on energy prices for industrial needs in the

short term and on retail electricity prices in the medium term. This would favour restoration of the industrial ecosystem and the

creation of new businesses, which are currently held back by high energy

costs and would benefit from the sustainability offered by this unprecedented

source of abundant clean energy. The low cost of energy would give

access to markets other than that of electrical energy, such as transport and

civil and industrial heating, now dominated by hydrocarbons, and the

respective industrial sectors. The type of innovation is mechatronics/aerospace and the most innovative element

with respect to the state of the art is certainly the wing. The availability

of an instrumented and implemented power wing is the principal enabling and

exclusivity factor for large-scale generation of cheap energy from tropospheric wind. The concept of a wing of such great

power is totally new. The laboratories around the world that have

successfully reproduced the KiteGen tropospheric wind generator have shown an energy

production and limit of a few dozen kW due to use of inadequate sport kites. KiteGen conducted an investigation on the wing at a very

early stage, which seemed essential in order to reach utility scale,

achieving a performance at least one hundred times that of small-scale

systems, which produce expensive energy and find no path towards incremental

scalability. KiteGen therefore represents a leap in

quality to give birth to the economic sector of tropospheric

wind energy, made possible by megawatt class generators. Moreover, the

modular design or, more simply, the kite wind farm concept, could even be

scaled to the gigawatt class, i.e. to compete with

the broader segment of the fossil fuel energy market. CONTENT AND OBJECTIVES OF THE PROJECT

KiteGen is well advanced in the research

and experimentation of the High Altitude Wind Power (HAWP) concept. The

innovations and results have continued at a considerable pace, with less

attention paid to common perception and possible comprehension, albeit

unintentionally, as this would have been an unsustainable cost and

commitment. This has resulted in a widening of the cognitive gap and

noticeable cognitive blocks, both in academic theoretical progress and in

many scientific publications on the emerging science of KiteGen.

One goal of the

project is to create and broaden understanding of the project scenario in

order to establish or recompose a critical mass of players that can

creatively guide the industrial initiative and the strategic relationships

required for its foreseeable status as a large industry. There is therefore

an essential need for effective training support, which should be provided by

the institutions in the region. The stakes are high, the energy market is

virtually untapped, abundant and very receptive, and the current objective is

also one of organization, as the project can now pass from the hands of the

scientists, designers and prototype builders to those of the technicians who

optimize production, including production line equipment. From this

perspective, collaboration with industrial partners, like that with our

composite manufacturer, is of strategic importance in order to address the

issue in the area of know-how with the very high quality standards required. In order to justify

the path taken by the project, which was arbitrary only in appearance, we can

affirm that we have discovered and documented that it is subject to

thresholds of scalability, which reside mainly in the design sizing of the

power-to-weight ratio of the wing: •

Up to 80kW nominal power, implementation of the technology is simple and many

laboratories have successfully reproduced and confirmed experiences very

similar to Mobilegen, our first 40 kW KiteGen generator, which only required a few weeks of

work for its construction and functional operation, using wings designed for

sports purposes. All possible evolutions have already been explored at this

power level, including the production cycle and automatic flight with

multi-predictive control software. •

In the 80kW - 3MW range we have tried various solutions: if the wing is large

and made from cloth (dacron sail fabric), it gives

way under stress and/or performs inadequately; if it is rigid and made from

composite material, it is too fast and control intensive and requires more

wind for takeoff, as well as a generator robot with a long enough arm to

provide sufficient space for the necessary manoeuvres. • Finally, a sizing

of 3MW (or above) has enabled us to show that a large composite wing of 130 m2

begins to support itself when flying at 14m/s and with 2 m/s of natural wind,

which is already quite manageable in terms of the take-off. However, the manoeuvring robot permits no approximations, as we are

talking in safety terms of a sizing of over 40 tons of cable pull and a

double arm to support the wing at rest in an unfolded configuration. The general design

rule that the tests of the various KiteGen

prototypes have highlighted is that as the wing becomes larger and more

efficient, and simpler in technological and operational terms, the ground

robot becomes decidedly much more demanding, with much greater performance

requirements. Obviously, the robot is simply a special machine that has to

respond to clear specifications, and therefore only requires sound

engineering practices, without involving design uncertainties. The solution

to the problem of scalability, which necessarily must tend towards very large

versions, both in terms of size and of power, was based on

physical/aerodynamic issues rather than strategic choice. This step has been

similarly encountered and confirmed by all the laboratories around the world

that have replicated the KiteGen experiences with

similar success. As might be

expected, the KiteGen project is beginning to

become known and recognized by stakeholders. We are also the only Cleantech “100 to watch” company from Italy and the only

one in the world dealing with renewable energy. Nevertheless, we often

encounter criticisms in the social media, some very agitated and others

accusing us of an attitude that can be described as “megalomania”. This

is certainly an opportunity to explain that the main reasons for the

disproportionate sizes are the global energy problem and the undeniable

magnitude of the untapped field that KiteGen seeks

to exploit. KiteGen is merely a light, enabling

technology that allows effective utilization of this field. In a similar way to KiteGen, the phenomenon of “horizontal drilling”, which

has revolutionized the hydrocarbon sector, was not understood immediately.

The mere invention of a technological support cannot be accused of being

disproportionate, although the results are known and highly relevant. Put another way, the

invention of the fishing rod bears no responsibility for the large amount of

fish in the sea, but fishing rods can feed an entire population. Consequently, it can

be clearly understood that if we are speaking of exaggeration, this does not

apply to KiteGen. However, the evident incapacity

of the institutions to relate appropriately with KiteGen

in order to verify the programme’s undoubted

strategic importance, which KiteGen has highlighted

and is offering to the country, is unjustified. Yet important events in the

energy sector always involve the direct participation of the institutions and

governments of the world.

BRINGING R&D ACTIVITIES TO AN ADVANCED STAGE IN

RELATION TO ENTRY INTO THE MARKET

The R&D work

carried out by the proponent, also as part of the co-financed regional

project “Wings & Power”, has led to an advanced stage of development and

the achievement of TRL7, as recognized by ENEA (the Italian National Agency

for New Technologies, Energy and Sustainable Economic Development) in the

parliamentary audition dedicated to tropospheric wind

technologies held on 08.01.2015

http://www.infoparlamento.eu/index.php?option=com_mtree&task=att_download&link_id=5774&cf_id=76. Having achieved this

goal, our activities have been focused on the industrialization of the

technology through validation of the components and their specifications, in

view of bringing most of them up to TRL 8. This proposal is therefore

motivated by the need to accelerate the start of production and reduce the

time to market. The public support required, far from significantly covering

the costs of industrialization, which amount to €80 million, is mainly geared

towards recognition and acceptance of the previous R&D work and the

future industrial development, with its corollary of employment and

attraction of new investments. This recognition is in itself an engine of

trust and cooperation on the part of the numerous companies in the region

which will be involved as suppliers. STRATEGIC NATURE OF THE INTERVENTION

Sequoia Automation,

the proponent’s operational partner company, was created specifically (from

the sales of a business unit in 2006) as an engineering research and study

centre devoted entirely to the KiteGen project.

Therefore the finalization of the project, with achievement of the

industrialization of the product, is its prime and founding objective. The

R&D activity has been part of a well-defined strategic plan, as is the

validation and industrialization activity currently in progress. The public

intervention received in support (the aforementioned “Wings & Power”)

would also have permitted a corporate reorganization, necessary for shifting

the focus of the personnel and facility from the R&D phase to that of

industrialization, had it not been reduced from the original €7 million to

less than €3 million, resulting in increased difficulty in recruiting,

training and retaining the necessary highly skilled personnel. This

reorganization is therefore still pending and increasingly urgent and

necessary to avoid having to sell the technology as a whole, presumably to major

foreign players. IMPACT ON INDUSTRY AND ON THE CORPORATE AND

PRODUCTIVE STRUCTURE

Energy production

from renewable sources has two available global markets. The first, which is

worth US$500 billion a year in terms of investment based on COP21 and the

Kyoto Protocol, includes a share for innovation and massive support for

serial deployment of mature sources, mainly wind and solar power. The second

is the far more important energy market, which includes fossil fuels. In the

short and very short terms, if properly informed regarding the potential of KiteGen, the first market could divert significant

proportions of its funding for the support of this innovation and the

deployment of KiteGen. It is sufficient to mention

the Breakthrough Energy Coalition established by Bill Gates, which aims to

invest $2 billion in innovation and has already publicly mentioned KiteGen and the HAWP sector as projects worthy of

attention. After the project

for the first industrial production batch, the partner companies will have

acquired the expertise and capability to produce the most important parts of

the system: the wing, sensors, light electronics and software. They will also

have acquired the capacity to manage the logistical and technical

coordination of a supply chain for all the other components, including

mechanical and electromechanical parts, power electronics and cooling

systems. This capacity will enable the subsequent production and installation

of batches of generators in the order of hundreds of units per year. Putting

the generators into production will require the establishment of companies

dedicated to the maintenance, supervision and operation of the plants. The competitive

advantage acquired thanks to the intellectual property rights and industrial

research will allow the implementation of a strategic plan for the expansion

of the production capacity in the order of thousands of units per year. The

direct employment of resources in Piedmont (including partner companies and

linked activities) to enable the launch and operability of the initiative can

be estimated initially at around 30 researchers for R&D activities, 10

administrative operators for human resources, administration and procurement

activities, 10 sales managers for global wind farming start-up activities and

120 other workers including production operatives, maintenance technicians

and product engineers for the manufacture of the KiteGen

generators in the factory. The total initial employment will be at least 170

people at one year from the start of the initiative. By the second year,

another 100 workers will be needed for the construction and the maintenance

of the KiteGen generator fleet. Subsequent

expansion of production to batches of thousands will result in an increase in

employment to over 2,000 workers. IMPACT ON THE REGION EMPLOYMENT

The project, if

implemented, will guarantee an extremely high return of employment, plausibly

in the order of hundreds of thousands of workers. This is because once the

competitiveness of the energy produced with this technology has been

verified, the market will expand in a predictable and calculable manner,

justifying the promise. This return of employment may also be seen in the

creation of an industrial chain ranging from the manufacture of the machines,

wings and cables to the installation and management of tropospheric

wind farms (wind farms), which can also lead to redevelopment of the areas most degraded in environmental terms and the

possibility for local authorities to become energy autonomous and/or energy

producers. These more than

reasonable certainties are based on: 1) An energy field

of unimagined magnitude (the tropospheric wind

harvestable from Italy amounts to at least 100 times the exports in

equivalent energy by Saudi Arabia) 2) The ERoEI of KiteGen technology,

which is 5 times that of the best crude oil during the economic boom of the

1950s (30 times that of traditional wind power, 90 times that of photovoltaic

energy and 270 times that of CSP) 3) An

incontrovertible theoretical basis: Google Scholar displays over 350 results

on KiteGen 4) Great experience

and architectural and technological clarity acquired by the proponent 5) Extensive

indicative experimentation necessary for a breakthrough technology, which has

also provided the “proof of concept” of the energy production cycle 6) Non-intermittent

nature of the source. INDUSTRIAL INVESTMENTS

Downstream of the

project for the first industrial production batch, it will be necessary to

expand the supply chain and linked activities, as the electricity sector

worldwide requests the installation of 2 million KiteGen

generators in 20 years. This results in an increase in the production

capacity in the order of 10,000 times that implemented for the first batch.

The light logistics and high added value of the mechatronic

parts of the product eliminates the need for exasperated optimization of the

production costs through outsourcing and leads to a hundred-fold increase in

value, to the benefit of the host region, attracting investments in the order

of tens of billions of euros. Electricity

production and showroom initiatives, such as the kite farm/campus in Giaveno, and an adequate expansion of current

technological and public and private research centres

will be required to provide the personnel training and R&D necessary to

keep the product updated and competitive. INNOVATIVE IMPACT OF THE SOLUTIONS INTRODUCED

KiteGen is the worldwide owner of the

best tropospheric wind energy technologies The impact of tropospheric wind energy is disruptive because the

electricity produced at the projected cost enters directly into competition

with thermal sources and transport fuels. With an electricity cost of less

than €15/MWh, synthetic diesels produced by capture

of atmospheric CO2 and extraction of hydrogen from water become

competitive with that obtained from fossil sources, thereby accessing a TAM

(Total Available market) of $8,000 billion/year, i.e. the entire current

energy market. It follows that the innovative effects of the proposal will

also impact sectors other than electricity generation and radically affect

their processes; for example, boosting heating/air conditioning in both

summer and winter via high efficiency heat pumps (already cost-effective compared

to retail electricity costs at below €90/MWh),

electric cooking (e.g. induction cooking), the recovery of transport battery

materials, jet fuel, electro-foundries, metal smelting, metal forming,

silicon refining, desalination, fertilizers, etc., decisively stimulating the

various related industries. COMPETITIVE

SCENARIO

|

|

For the sake of brevity, assertive

evaluations will follow. They can be documented and debated with due

accuracy. KiteGen is always open to exchanges at

the best competence tier of the sector. In fact, KiteGen

worst hindrance is indeed the lack of forethoughts while establishing energy

policies. Generic innovations in energy KiteGen concept arose in 1999 after an

analytic research on possible future energy sources, lead by CESI (now RSE)

and GRTN (now Terna), with a key contribution from

professor Luigi Paris (father of Italian electric energy). The strict method

used allows us, even as of today, to affirm with proof that KiteGen has a Q factor from 30 to 1000 times greater than

the most notorious actors in this field, and is the one and only able to lead

the transition from fossil fuels. Following examples confirm what we

just stated. Sea power

Pelamis, WaveDragon,

Oyster Acquamarine, Scotrenewables

Tidal Power, Pewec di

ENEA, OTEC Wind power

Beatrice, AlfaVentus,

London Array, El Hierro, Sandia 20MW HWT Solar energy

Ouarzazate, Andasol,

Topaz Solar Farm, IBM Sunflower, Ivanpha, Archimede Nuclear and coal

ITER, CCS, IV generation reactors HAWP

competitors

KiteGen has been the pioneer of high

altitude wind power, and kept on pushing to increase its theoretical and

practical advantage over supposed competitors, having industrial-scale

production as declared objective. As owner of international patents, KiteGen is also free to operate, while having the right

to require overlapping operations (or right out counterfeiters) to cease

operations. KiteGen concept is generally seen as

the best in terms of feasibility and potential over present international

competitors (Makani, Altaeros,

Wind Lift, Skysail, SkyWind Power, Magenn, E-Kite, KPS, Ampix, Twind). |

Other reading about theme

|

|

Italian

http://www.enzopennetta.it/2016/03/cs-intervista-massimo-ippolito/

http://kitegen.com/pdf/giancarlo-costello.html English http://euanmearns.com/high-altitude-wind-power-reviewed/

http://kitegen.com/pdf/Abbate_We_need_more_energy_Eng_final.htm

|

|

|

|

|

|

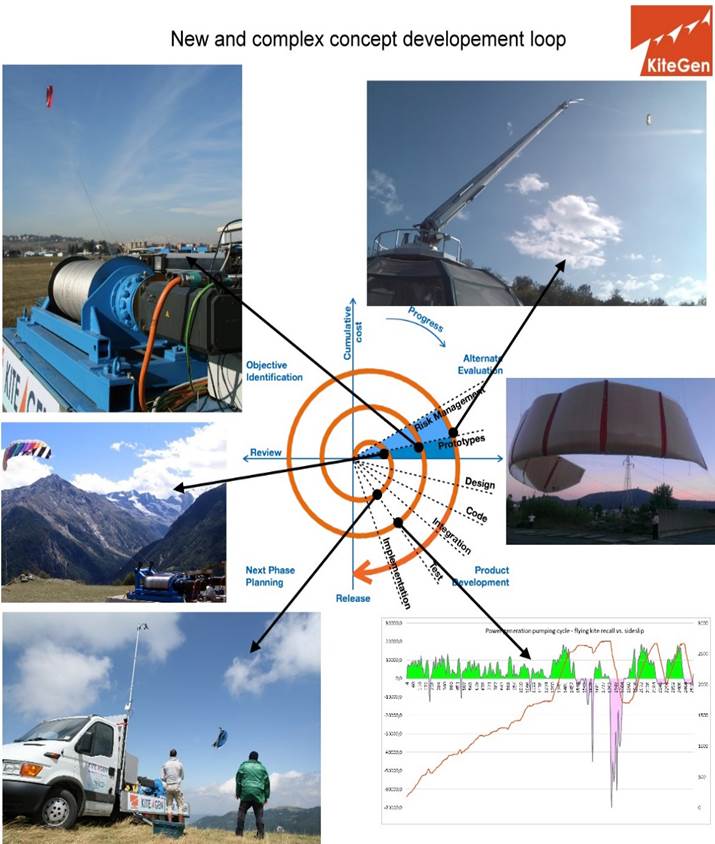

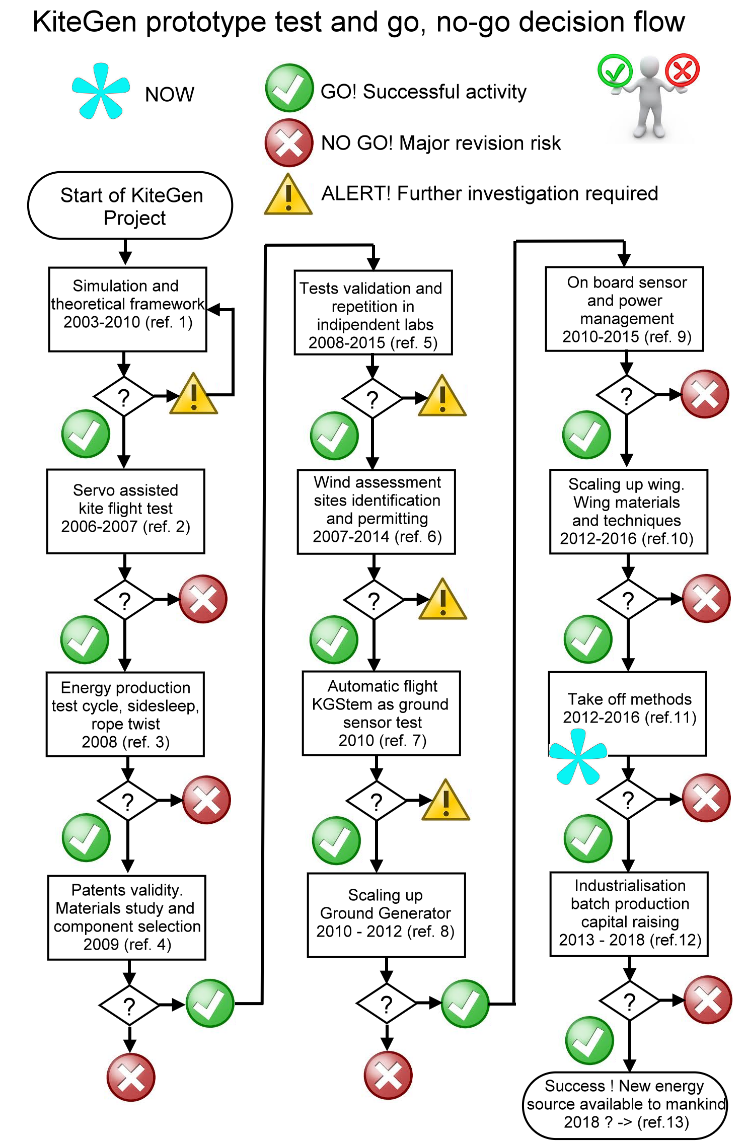

The steps of KiteGen project through prototype testing and

decision-making process

Life-cycle analyses confirm these

figures. In our practical industrial design, this huge performance increase

is exploited not to reach high power peaks instead to increase energy

availability through the year, avoiding significant power fluctuations. In

this way, generator production gets near to a baseload-type

performance, almost solving intermittency issues. This production target obviously

implies a mature system, nurtured by substantial investments aimed at

technology development. The improvement we can nowadays esteem for our

prototypes is 16-fold. Definitely remarkable, yet dragged down by some

limiting factors like machinery heat balance, issue not yet tackled and

completely solved.

|